As promised in the last article, today I will tell you about the experience of using rust removers (iron restoration).

Until the beginning of the restoration of the Volga, I had practically no experience with rust converters. It’s not that I never used such preparations, I treated them of course, but these were small, corroded areas under the paintwork. Therefore, I did not have a visual effectiveness of their use, and I did not particularly believe in their effectiveness.

Since I operated the car carefully, followed it, there was no rust anywhere. There were several pockets of corrosion on the front end (under the clutch cylinder where the brake fluid was leaking), a little on the corners of the doors (on the inside), and along the lower threshold weld.

When I began to clean up the body parts damaged by fire, removing the burnt paintwork and anticorrosive, I tried to rip everything off to bare, shiny metal. When I came to the garage the next day, I saw a rusty coating on the surface cleaned yesterday, formed from moist air.

Well, imagine my disappointment. You scrape and scrape the metal, and then you see this as a result. There was still a lot of work ahead to clean up the soot, and it was far from painting.

The question arose of how to protect pure metal. I decided to try a rust converter. Went to the store and bought what was in stock. One bottle of the "Tsinkar" converter, from the company "Agat-Avto", and the second "Antiruster", from the company "Astrokhim". Both drugs contain zinc, but manganese is also present in the "Tsinkar" converter in addition to zinc.

You won't find rust converters with such names in your stores, but the essence of this does not change. All these drugs have a similar composition: phosphoric or orthophosphoric acid, a little distilled water, and additives in the form of zinc and manganese. The acid converts iron oxide to phosphates, zinc protects against electrochemical corrosion, and manganese gives the effect of an alloyed surface.

I used the "Tsinkar" converter before, so I "trusted" it more.

I will immediately dwell on one detail regarding the quality of the bottles. At the converter "Tsinkar" the work of the atomizer was enough for only half of the bottle. Then he could not stand it and broke down. I had to use another one, from a window cleaner. But the converter of the company "Astrohim" had enough stock for five bottle volumes. In the process of processing, I bought more "Tsinkar", without a sprayer, poured a bottle into the "Antiruster" and sprayed from it. The atomizer is still alive, left him.

From the point of view of the effectiveness of drugs, there are practically no differences. Both contain phosphoric acid, both contain zinc. Both form a gray surface when applied to bare metal. A small rusty coating is transformed as if it never existed.

With loose rust, which cannot be removed even with a reinforced cord brush (with thick wires), you should do this (this is already from my personal experience):

- Copiously sprinkled on a rusty surface and left for a day.

- The next day, come and rip it off with a cord brush. Almost everything that was not deleted before will be deleted.

- What will not be removed is exactly the same again: they sprinkled it, left it for a day, they came and ripped it off.

So, I cleaned a rusty spot on the inside of the left wing, formed a month after the Volga was burned. On the front left pillar, which is located above the wing, the water that has collected on the roof flows down and falls directly on the inner plane of the wing. Well, since the anticorrosive has burned out, get rust.

Here are excerpts from the article "Prepared for priming the front fender".

So, what happened before the purge.

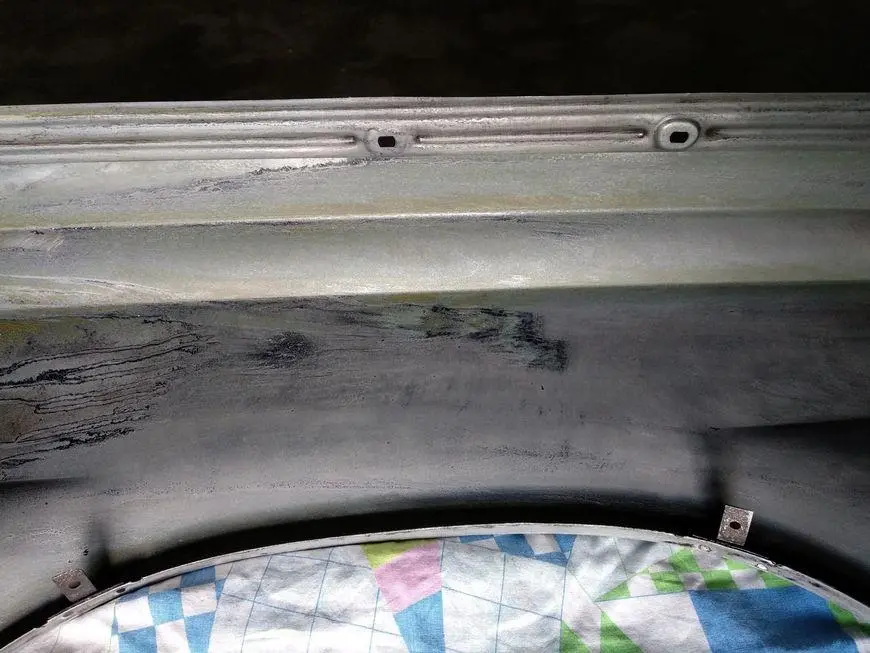

After stripping and single processing by the converter Tsinkar.

Processing with the converter "Tsinkar" was carried out on a vertical surface (the wing was on the floor), hence the black smudges. This is how the acid drains, taking with it the loosened particles of rust. Well, since the technology says that after processing the part must be left alone until completely dry, which I did, then all this dirt was deposited and dried along the runoff path. In principle, all this is easily cleaned off (this is also mentioned in the instructions). Even that rust is cleaned off, which was held very firmly, and which the cord brush did not take. So, after several treatments with the Tsinkar converter and mechanical cleaning, everything was cleaned off, and the surface acquired a gray color (coated with zinc). By the way, each time I cleaned the dried surface not with a hard, but with a soft cord brush, so as not to clean off the zinc layer. The operation was repeated three or four times.

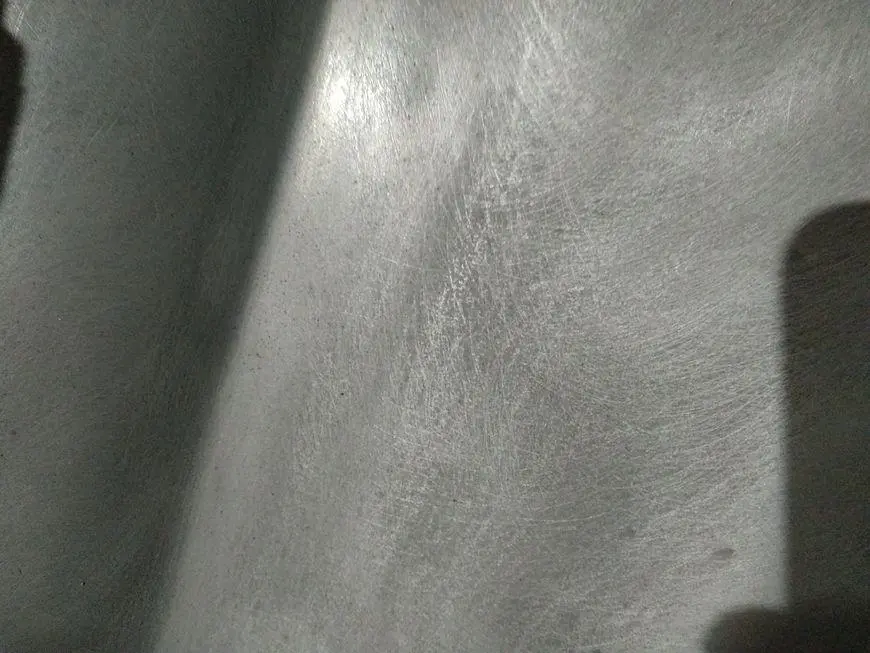

In the end, this is what happened:

The instructions for both preparations say that the treatment should be carried out immediately before coloring, a maximum of two days. After that, you need to repeat the procedure. Indeed, the processing was enough for no more than a week. Then rust started to appear again. I had to spray several times, for a month and a half.

Another nuance is how to remove the acid itself from the treated surface before priming.

On the preparation of the company "Agat-Auto" it is written that you can simply wipe off the dried residues with a rag or brush, but it is not specified which brush. An ordinary hairbrush does not take these residues. I tried it with a soft cord brush, it removes it, and it seems that it doesn’t even spoil the surface. But still, it’s scary, you hope for zinc protection, but you tore off all the protection.

On the preparation of the company "Astrohim", it is written that after applying it, you need to wait 20 minutes and rinse with water. I tried this and what did I get? Completely rusty surface, that's what. Before my eyes, when the water dried, the treated surface turned into one large yellow spot.

I thought I thought what to do and came up with. I treated the surface with a preparation, waited 20 minutes, and washed it off with kerosene. It worked out great. Kerosene sprayed profusely from the sprayer. As a result, all the acid was washed away, and the surface turned out to be dark gray.

Kerosene then weathered for another week. And after it dried, rust no longer appeared until the painting itself.

Before painting, I treated the entire surface with a degreaser (anti-silicone) and began to primer.

That's all. Until next articles.