All preparatory work before painting my "Volga" were completed. The body of the car was coated with an acid primer and primer-filler, sanded, smeared with sealant, and protected with anticorrosive. I wrote about all this in previous articles. Today's story will be about painting.

The action plan was:

- Apply two coats of HB BODY 970 insulating primer. As it turned out, the second coat was my big mistake!

- Apply 3-4 coats of MOBIHEL base enamel.

- Apply varnish HB BODY 699.

I did an overview of all the components in one of the articles.

Painting was done on August 14, 2019, the air temperature in the garage was approximately 24 degrees Celsius (good temperature).

Apply the first coat of primer-insulator. Waited about 30 minutes. The primer fit perfectly. It spread evenly, and when it dried, it stretched even more and began to look like a transparent film with a matte sheen.

I began to apply a second layer, and ... ruined everything. The primer did not spread at all, remaining in the form of drops. However, with the second coat, I "walked" over the entire surface, deciding that I would apply another layer. After another 30 minutes, I applied the third layer. At the same time, I opened the supply of material (primer) a little more to make the layer thicker and fill in all the bumps. Let me tell you, it helped, but not much.

I didn't even think about putting off painting, waiting for the primer to dry, sanding it off, and reapplying one coat. Thoughts ran in different directions. Let me remind you, this is my first car painting. Now I understand that it was necessary to do so.

In general, I waited about an hour, and began to apply the base enamel. Here, too, not everything went smoothly.

Usually, pictograms are applied on cans with paint materials on how to use this or that material. This is a kind of brief technical data sheet (TDS - Technical Data Sheet). On one of the pictograms of the can with the base was drawn: "Thinner 40%". I began to wonder if this is the maximum possible amount of diluent that can be added, or is it recommended? Later, about a year later, I bought a viscometer, measured the viscosity with a stopwatch, it turned out that 40% is exactly the amount of thinner at which the base enamel acquires the necessary consistency for high-quality application.

Here, in order to understand the timing of restoration work, it must be said that I restored the car in an unheated garage, only in the summer season, approximately from mid-April to mid-October. Therefore, the work was delayed for several years. But in the winter, there was time to read articles, watch videos, and learn from professionals through these sources of knowledge.

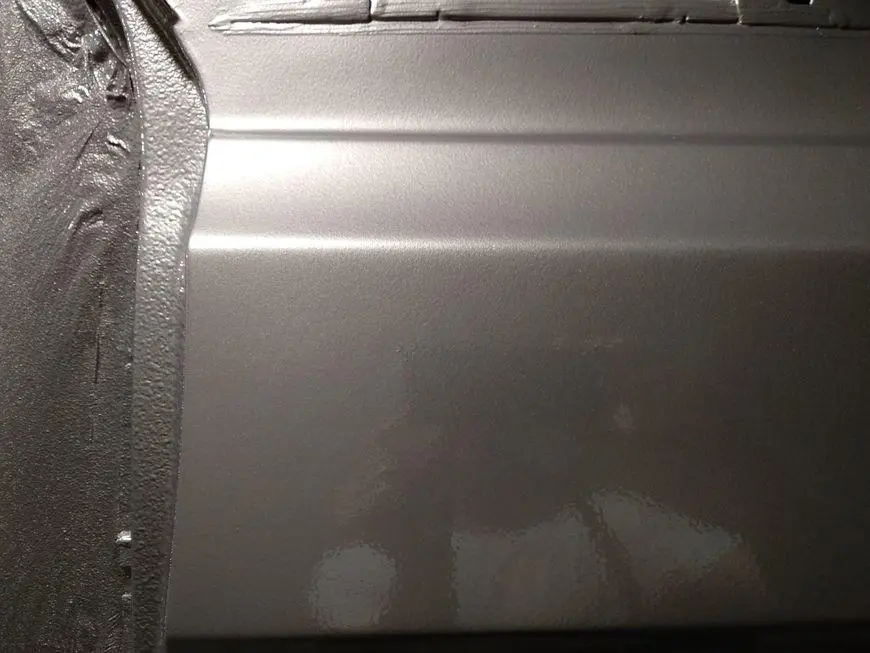

Let's return to "our sheep". In general, I first applied the base enamel in a small jet. I thought it would take too long. I added material feed, made the jet bigger. And of course, on the side surfaces received smudges. Huge in some places. Once again, I was shocked.

And this situation could be corrected. It was possible to wait until the base enamel was dry and carefully paint over it with a small jet, supplying less material and air. I did so afterwards.

Instead, I tried to blur the smudges with a thinner. As a result, the enamel was simply washed away.

Began to think how to be. I used materials, but there is almost no result. I thought, if you leave it like that, without varnishing, then the base enamel was then applied in vain. If I cover it with varnish, then I will spend more material, but I will save the main part of the normally applied enamel. As a result, I decided to apply varnish.

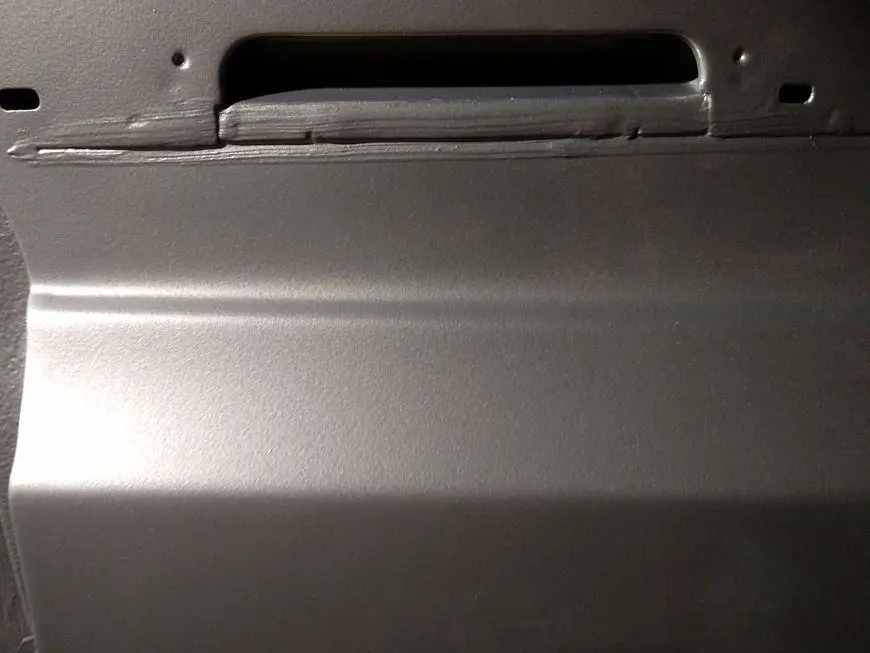

Lacquer lay more or less evenly. But also, not without surprises. In one place, the hose touched the painted surface, in the other it received small smudges.

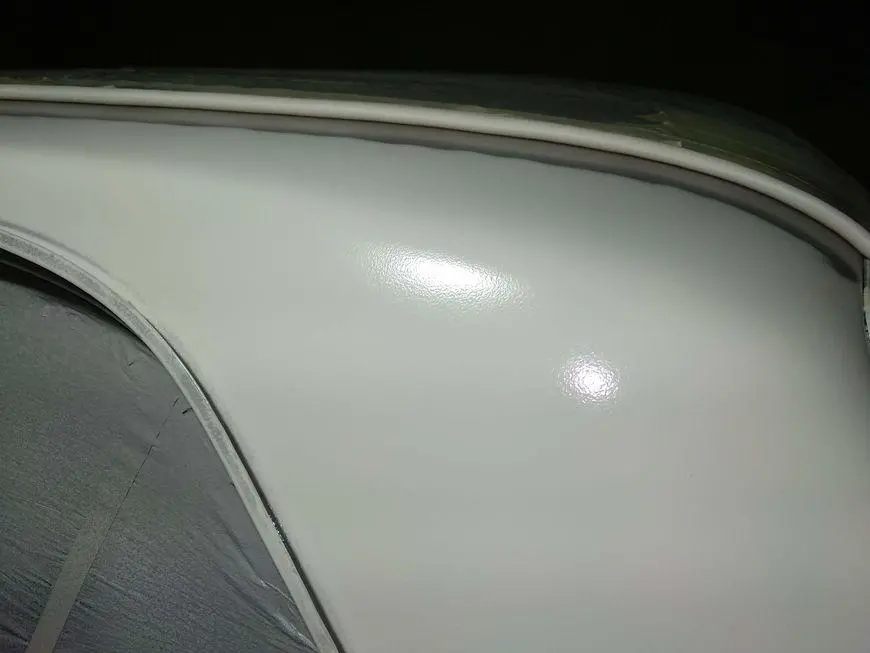

See what happened.

That's all. In the next article I will show how I corrected the errors of unsuccessful painting.