Let me remind you that I repaired the Volga in a removable garage box. The dimensions of the box are not large - 6 meters long, 2.8 meters wide. It was not easy to repair such a "ship" as the Volga on such an area, given that I dismantled almost half of the car, and kept the removed parts in the same garage.

The hood, trunk lid, left doors, windows, front bumper was removed. The rear bumper was thrown into the trash. When I repaired the left doors and put them in place, I moved to the second side. In general, the doors hung on hooks all the time, against the back wall. I wrapped the trunk lid in blankets and put it on the floor, along the left wall, closer to the rear corner. The hood, as the largest body part, lay above the car, on wooden logs resting on shelves.

I went to the most important thing - to the shelves. The shelves in the rented garage are very handy. If it weren't for them, I don't know how I would have made the repair at all. Without shelves, everything listed above would lie on the floor in the aisles.

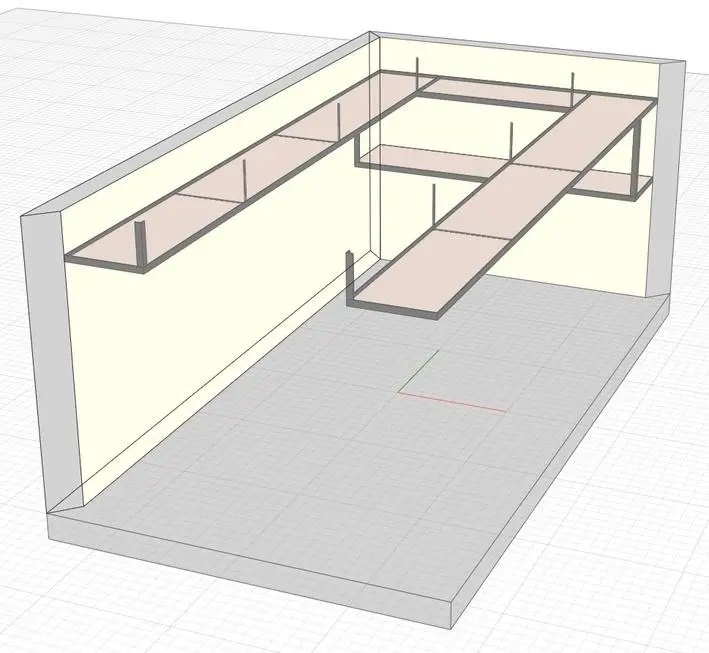

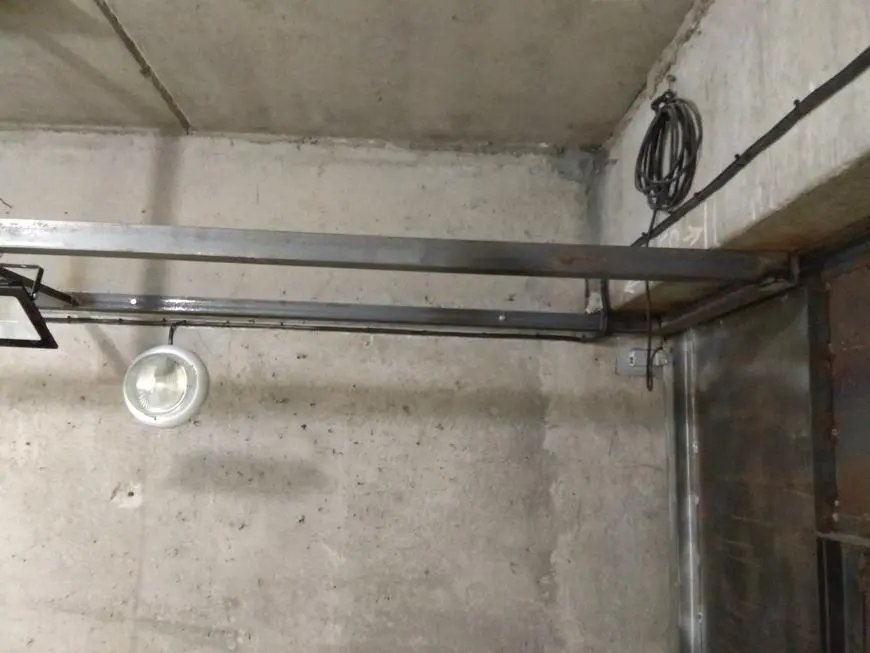

Shelves are located along the side walls, from the gate to the back wall. The width of the shelves is 500 mm, the level of attachment from the ceiling is also approximately 500 mm. The garage itself is 2500 mm high. There is no shelf on the back wall.

In October last year, after thinking about where to put the Volga when I have to vacate the rented garage (the garage was paid for until January 2022), and also wanting to remove from the loggia: wheels, a drill, a hammer drill, a grinding and polishing machine and other “necessary” things, my wife and I decided to buy our own garage. In the same garage complex, I found someone who was selling a garage, agreed on a price and bought it.

The purchased garage, at the time of purchase, was also occupied by a tenant who was let in by the previous owners. The garage was filled to the top with building materials. I had to wait until the beginning of November until he takes them out.

The garage literally looked like a BOX - only bare walls, floor and ceiling. There was no point in putting a car there, how to repair it later. And besides the car, you can’t place anything else there. I bought it before winter, not quite on time, it was about -10 degrees Celsius in the garage. Nevertheless, I decided to urgently make the same shelves as in the garage I rented.

I made a drawing, calculated how much and what material is needed. I purchased the fiftieth corner for the manufacture of the frame of the shelves. For the flooring of the shelves, I bought a lining (finishing board) to make it look beautiful. At the back wall, I decided to make a workbench tabletop, similar to the same shelves, but with a fiftieth floorboard laid along.

I marked the places where the corner was attached to the walls with a level and began to mount it. Everything that was attached to the walls, I did alone. When it was time for welding, I called my friends to help.

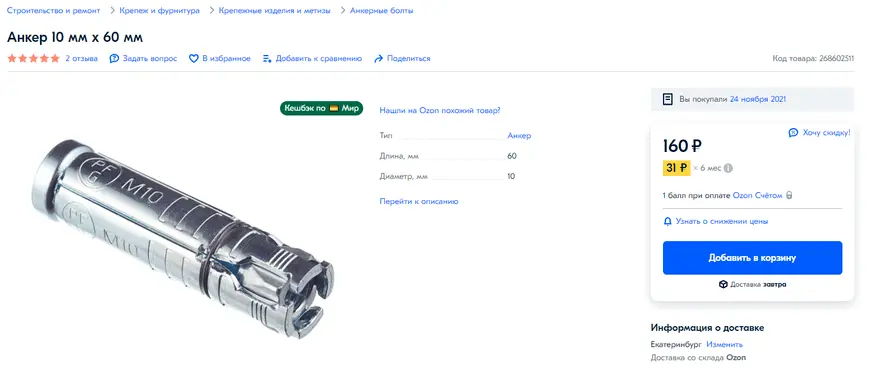

The inner frame of the shelves was attached to the ceiling with M10 x 60 mm anchors.

In some sources it is written that such anchors are intended for installation only in the compressed part of the slab, in others - in compressed and stretched. The ceiling (lower part of the slab) is a stretched zone, and therefore it seems to be dangerous to put them there, when tightened, the concrete may burst. But I didn't overtighten the bolts. He made sure that the expansion part of the anchor unbent in different directions, and then loosened the tightness. Holes in the slab were drilled in the middle of the hollow channels, so that all four expansion plates of the anchor were unbent. I liked the anchors.

After installation, the strength of the structure was checked together with a friend, pulling himself up with his hands on the frame. Holds tight.

In parallel, I began to install new electrical outlets and electric lighting. By the way, there were no sockets in the garage at all. There was one broken-down socket hanging on the wire, next to the gate, and that was it.

Somewhere towards the end of November, I finished installation, and began painting work.

I painted with a cheap paint sprayer, which I started with, painted the car, before buying a second, better paint sprayer.

In the presence was a three-liter can of white primer-enamel for rust from the company "TEKS", stood on the balcony for two years. Additionally, I bought two cans of three liters of PF-115 enamel. I bought enamel at OZONE.

I wrote a review on OZON about how I applied these enamels. I quote:

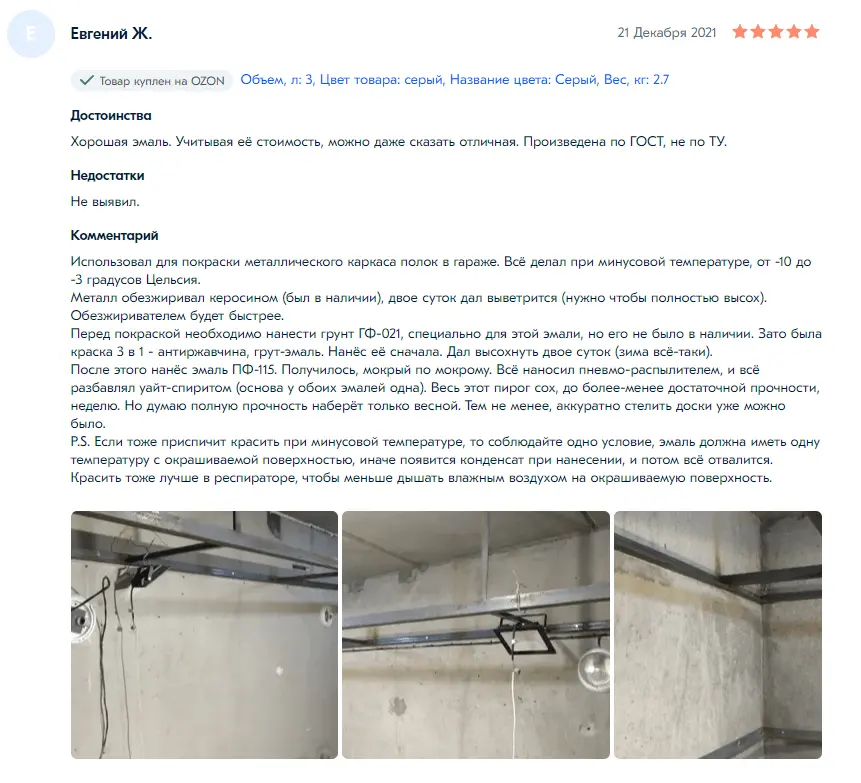

I used the enamel for painting the metal frame of the shelves in the garage. I did the painting at sub-zero temperatures, from -10 to -3 degrees Celsius.

The metal was degreased with kerosene, because it was available. Kerosene weathered for more than two days. If you degrease with a degreaser, it will dry faster.

Before painting, it is necessary to apply primer GF-021, especially for this enamel, but it was not available. But there was a primer-enamel 3 in 1 - anti-rust, primer and enamel. First, I painted with this primer-enamel. I let it dry for two days (winter after all).

After that, he applied PF-115 enamel. It turned out, "wet on wet." I applied everything with a pneumatic sprayer and diluted everything with white spirit (both enamels have the same base). This whole cake dried, to more or less sufficient strength, for a week. But I think it will gain full strength only in the spring. Nevertheless, it was already possible to carefully lay the boards.

P.S. If you also want to paint at sub-zero temperatures, then follow one condition, the enamel must have the same temperature as the surface to be painted, otherwise condensation will appear during application, and then everything will fall off. It is also better to paint in a respirator in order to breathe less moist air on the surface to be painted.

Paint work finished in four days. In the review, he wrote that the “pie” had been drying for a week, in fact, two weeks, until the moment when I started laying the lining.

I finished the work by mid-December and drove the car and moved things from the rented garage a week before the new year. Until now, you go into YOUR garage, and it smells of wood and enamel. Pentaphthalic enamel, smells nice.

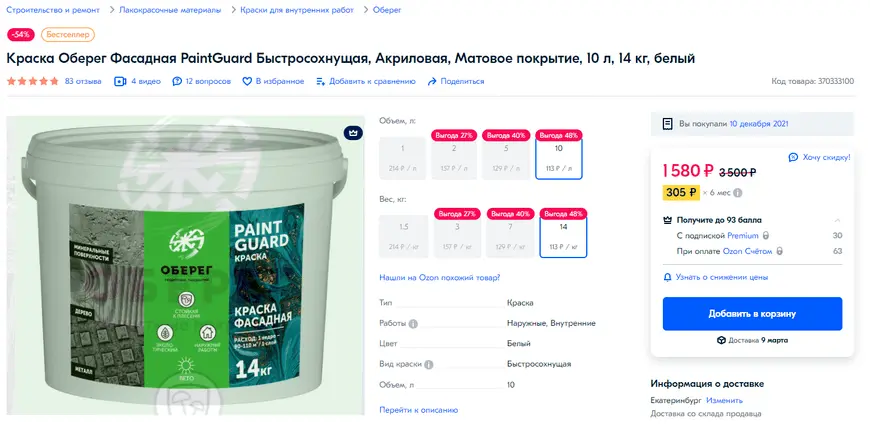

Plans to putty and paint the walls and ceiling in the summer. I have already bought facade paint for this. I keep the paint at home for now so that it does not freeze, since it is water-based.

Now the process and results of labor.

That's all, I shared with you the events and experience gained. Thank you for reading the article to the end. Please save my site in your bookmarks and visit it periodically. You can also share links to my articles with your friends and acquaintances. In this way you will help me in its promotion.